EtherCAT®

ADVANET Products

LoRaWAN® compatible general-purpose IoT node development kit

The development kit features the accessibility to try out Advanet "Leyline N1" general-purpose IoT node being compatible with LoRaWAN®.

Advanet development kit consists of two Leyline N1 built-in sensor boxes and one gateway.

A GUI has been built into the gateway that allows sensor data to be immediately viewed.

Evaluation can be initiated by simply turning on the power, making it ideal for customers who want to try out a few units at the early stage of PoC.

Therefore, data can be collected and evaluated from different locations, allowing the performance of Leyline N1 to be verified in conditions close to the actual usage environment.

For inquiries about this product

03-6834-2600 sales@toamec.co.jp

LoRaWAN® compatible general-purpose IoT node

This product is a highly customizable general-purpose IoT node supporting LoRaWAN® communications.

It is designed to enable management even in environments where person is difficult to reach. It can also improve business efficiency in various fields, including manufacture, real estate and agriculture by enabling remote controlling and automatizing devices.

Advanet IoT node is equipped with wireless communication functions and microcontroller in a compact size being just 4 cm3.

Combining with various sensors, it is able to control devices and obtain environmental data from both outdoor and indoor.

For inquiries about this product

03-6834-2600 sales@toamec.co.jp

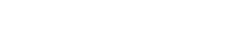

CC-Link IE TSN compatible PCI Express add-in card

CC-Link IE TSN is an industrial Ethernet protocol that utilizes TSN technology to provide time synchronization, real-time performance, and high-speed, high-capacity communication.

The AdEXP1589 is a manager/local board which compatible with intelligent CC-Link IE TSN in low-profile PCI Express add-in card type.

By adding it as an add-in card to existing industrial computers… etc, it can achieve CC-Link IE TSN functionality and offer many benefits including high-speed synchronous control, shorter takt time, easier to identify cause of problem…etc.

For inquiries about this product

03-6834-2600 sales@toamec.co.jp

Taiwan Pulse Motion Products

EtherCAT®Slave

DI/DO Module

EtherCAT® Digital I/O slave module.

Maxium channel: 96-Ch

For inquiries about this product

03-6834-2600 sales@toamec.co.jp

AI/AO Module

EtherCAT® Analog I/O slave module

Maxium channel: 8-ch.

※Other types of I/O module is also available. Connector type is also possible through customization.

Please feel free to contact us if you have any requirement.

※There are other variations of I/O module available.

We can customize and provide your required connector type.

Please feel free to contact us.

For inquiries about this product

03-6834-2600 sales@toamec.co.jp

Techno Products

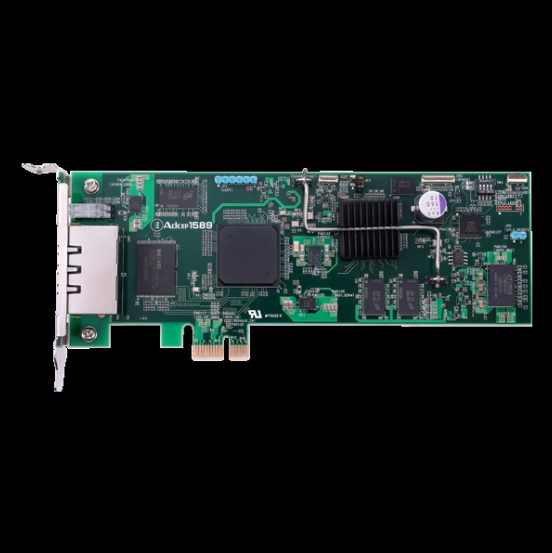

PC Based Motion Controller for EtherCAT®

PC Based Fine Motion

INtime, RTOS (Real Time OS), under the high-performance CPU of Techno PC ensure the reliability and stability. In addition to motion control and software PLC, you can construct your own control software. That is ideal for more advanced application. Eight(8) different machines can be controlled with one(1) system. Fine Motion has a track record of controlling more than 500 types of devices such as precision process machine (cutting, grinding, polishing, milling, boring, electric discharge, lasers, waterjet, etc.), coiling machine, winding machine, industrial robot, 3D printer, tube bender, spring manufacture, film roll, inspection equipment and others.

※PC / Windows / INtime / MECHATROLINK board / EtherCAT driver, must be purchased.

※The above block diagram is from the website of Techno.

For inquiries about this product

03-6834-2600 sales@toamec.co.jp

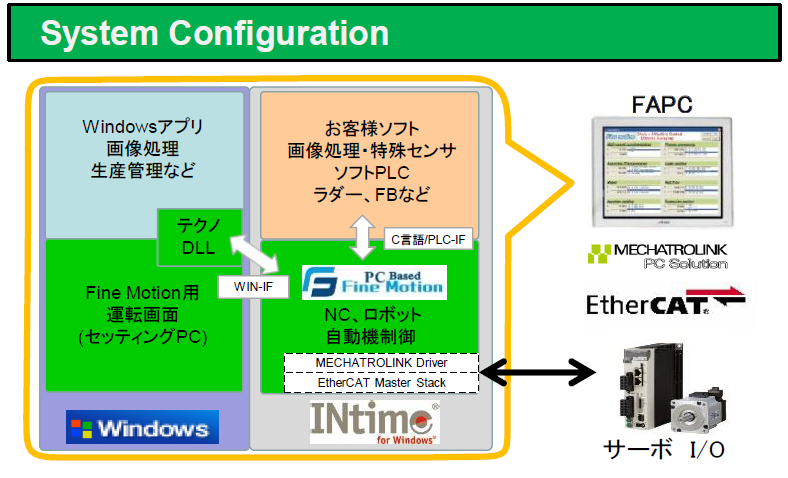

PC Based Motion Library

Techno’s PC Based Motion Library is C-language interface created from a part of fine motion. Installing the Library on your own software enables free development of your own motion control. You can use Visual Studio, the most-used integrated development environment in the world, to develop.

*EtherCAT version is compatible with the DC function and the servo amplifier conforming to CiA402 Drive Profile. Master Stack (RSI-ECAT/DC or AI-ECAT) must be purchased.

*PLC tool software and PLC is not required.

*The above block diagram is from the website of Techno.

For inquiries about this product

03-6834-2600 sales@toamec.co.jp

Panasonic Products

Motion Controller GM1

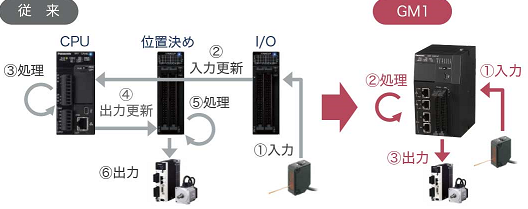

■PLC + Motion + Communication

Both RTEX type and EtherCAT type are available.

High speed motion control Fastest cycle 500μs

Multitask control by function aggregation

■Standardization of PLC programming

Break away from manufacturer-dependent programming. IEC61131-3 standard compliant. PLCopen supports 6 languages.

■Motion Various motion control is possible

- Motion and input / output control with the fastest control cycle of 500 μs (including expansion unit)

- Motion control that can be configured with 3 elements of real axis / virtual axis / encoder axis.

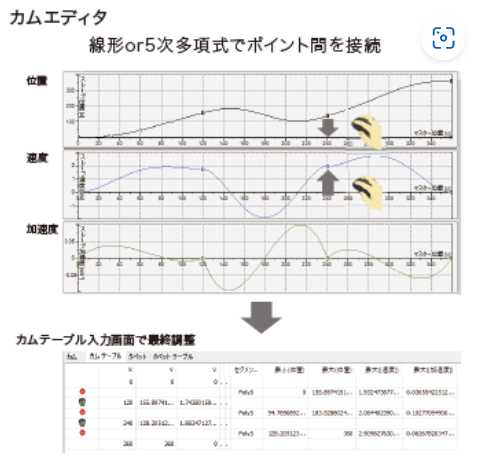

- Not only basic single axis control (position / speed / torque control), but also can freely generate a cam curve by the cam editor.

- Multi-axis synchronous control (gear cycle, cam cycle, interpolation control, CNC control) is possible.

- Adjustment is possible while looking at the position, speed, and acceleration curve of the slave axis using the cam editor.

Documentation for this product

https://www3.panasonic.biz/ac/j/fasys/plc/mc/gm1/index.jsp

For inquiries about this product

03-6834-2600 sales@toamec.co.jp