Automobile Facility

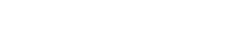

Ooi Sangyokikai Products

Ooi Sangyokikai can mainly design and manufacture automatic assembling machine and conveyance device for automobiles.

They can respond to requests from clients in various fields, such as CVT pully small system line, parts assembling machine of automotive, and magnetizing device of motor for air-conditioner.

Currently they are putting effort into HV and EV. If you are considering to manufacture automotive-related equipment, please feel free to contact us.

For inquiries about this product

03-6834-2600 sales@toamec.co.jp

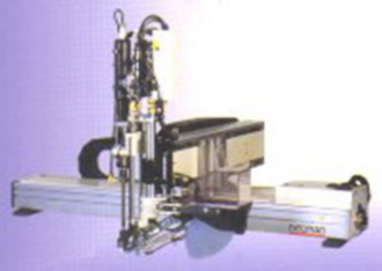

Creative Systems Products

They mainly design and manufacture machines for assembling and automatic feeding such as retainer cotter jacking machine and cylinder head assembling line.

Please have a look through product examples.

For inquiries about this product

03-6834-2600 sales@toamec.co.jp

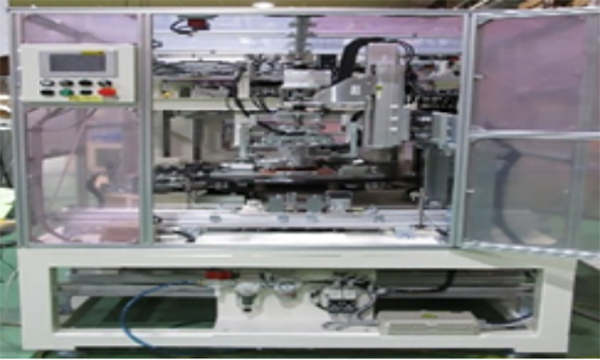

Toyooka Engineering Products

the biggest feature is that only tip of the tool can be switched automatically although conventionally spindle motor or switching attachment For each tool were required For replacement when using some tools in one robot. Enabling replacement of only tools achieved significant cost-reduction and space-saving at deburring robot system using plural tools. This technic of tool replacement function obtained a patent.

For inquiries about this product

03-6834-2600 sales@toamec.co.jp

Katsura Company Products

We deal in painting booth, drying furnace, environmental facility and automatic switching type adjuster. the heat exchanger For recovering waste heat of low-temperature adopts sensitive heat recovering type high-efficient aluminum-plate model to use at drying furnace and heating furnace.

For inquiries about this product

03-6834-2600 sales@toamec.co.jp

Nitto Seiko Products

Please contact us about Products of Nitto Seiko, general manufacturer of automating facility for using screw such as Screw tightening, automatic screw feeding and detecting screw height.

For inquiries about this product

03-6834-2600 sales@toamec.co.jp

Panasonic Smart Fact Solutions Products

Please contact us about CO2/MAG Welding Machine, MIG Welding Machine, TIG Welding Machine, Air Plasma Cutting Machine, Arc Welding Robot, Laser Welding Robot and Resistance Welding Machine

For inquiries about this product

03-6834-2600 sales@toamec.co.jp

Senju Metal Industry Products

Senju Metal Industry is the general system manufacturer of automatic soldering machine such as reflow furnace and local-flow soldering machine. Their experience and track record of soldering give customers suitable propositions.

For inquiries about this product

03-6834-2600 sales@toamec.co.jp

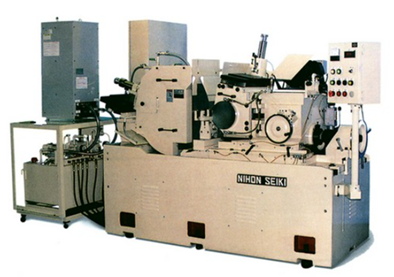

Nihon Seiki Products

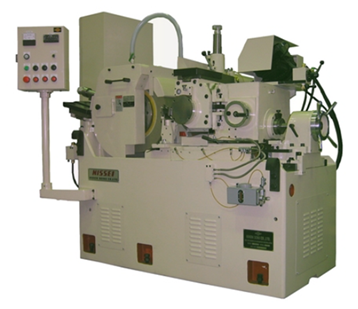

Center-less Grinder

Toamec has dealt in center-less grinder of NISSEI, a specialized manufacture with over- 50-years- experience. Nihon Seiki has designed and developed products from the point of operability and maintenance to supply them with proper specification at low-cost.

HGB-24NV /NWV /NSV

Specification |

HGB-24NV |

HGB-24NWV |

HGBNSV |

|

|---|---|---|---|---|

| Bearing | Dynamic Pressure Bearing | |||

| Grinding Stone Size | φ610×255×φ304.8 | φ610×305×φ304.8 | φ610×405×φ304.8 | |

| Adjusting Stone Size | φ330×255×φ170 | φ330×305×φ170 | φ330×405×φ170 | |

| Workpiece | ~φ125mm | |||

| Grinding Stone Rotation | 1,260 rpm | |||

| Adjusting Stone Rotation | 0~215 rpm | |||

| Adjusting Stone Angle | ~5° | |||

| Electric Motor | Grinding Stone | 22kW | 30kW | |

| Adjusting Stone | 3.7kW | |||

| Weight | 6,500kg | |||

| Mounting Requiring Area | 3,500mm×2,500mm | |||

BG-14H

Specification |

||

|---|---|---|

| Bearing | Dynamic Pressure Bearing | |

| Grinding Stone Size | φ355×102×180 | |

| Adjusting Stone Size | φ205×102×80 | |

| Workpiece | ~φ40mm | |

| Grinding Stone Rotation | 1,610 rpm | |

| Adjusting Stone Rotation | 0~215 rpm | |

| Adjusting Stone Angle | 5° | |

| Electric Motor | Grinding Stone | 5.5kW |

| Adjusting Stone | 0.75kW | |

| Weight | 1,200kg | |

| Mounting Requiring Area | 1,550mm×1,100mm | |

LGB-18HN /HNW LGB-20HN /HNW

Specification |

LGB-18HN |

LGB-18HNW |

LGB-20HN |

LGB-20HNW |

|

|---|---|---|---|---|---|

| Bearing | Dynamic Pressure Bearing | ||||

| Grinding Stone Size | φ455×205×φ254 | φ455×250×φ254 | φ510×205×φ254 | φ510×250×φ254 | |

| Adjusting Stone Size | φ270×205×φ120 | φ270×250×φ120 | φ270×205×φ120 | φ270×250×φ120 | |

| Workpiece | ~φ100mm | ~φ80mm | |||

| Grinding Stone Rotation | 1,260 rpm | ||||

| Adjusting Stone Rotation | 0~215 rpm | ||||

| Adjusting Stone Angle | ~5° | ||||

| Electric Motor | Grinding Stone | 11kW | 15kW | ||

| Adjusting Stone | 2.2kW | ||||

| Weight | 3,200kg | ||||

| Mounting Requiring Area | 2,100mm×1,800mm | ||||

LSG-20 /W

LSG-20 |

LSG-20W |

||

|---|---|---|---|

| Bearing | Static Pressure Bearing (Grinding Wheel Shaft) | ||

| Grinding Stone Size | φ510×205×φ254 | φ510×250×φ254 | |

| Adjusting Stone Size | φ270×205×φ120 | φ270×250×φ120 | |

| Workpiece | ~φ80mm | ||

| Grinding Stone Speed | Max 45m/sec | ||

| Adjusting Stone Rotation | 0~215 rpm | ||

| Adjusting Stone Angle | ~5° | ||

| Electric Motor | Grinding Stone | 11kW | 15kW |

| Adjusting Stone | 3.7kW | ||

| Weight | 3,500kg | ||

| Mounting Requiring Area | 2,500mm×2,500mm | ||

For inquiries about this product

03-6834-2600 sales@toamec.co.jp

※ワーク移動型、内径加工ブローチ盤等を取り扱っております。

Taiga Giken Products

Surface Processing Broaching Machine with High-Efficiency and High-Accuracy

- Low operation position as possible reduces loss of workpiece transportation and mounting.

- Specification of double or triple consolidation achieved to increase production efficiency.

| Model | Drawing Force (t) | Stroke (mm) | Operation Hight (mm) | Machine Hight | Mounting Area (width x depth mm) |

|---|---|---|---|---|---|

| TVS206 | 2 | 600 | 900 | 2500 | 900×1400 |

| TVS306 | 3 | 600 | 900 | 2500 | 900×1400 |

| TVS508 | 5 | 800 | 1100 | 3000 | 900×1600 |

| TVS712 | 7.5 | 1200 | 1500 | 3800 | 900×1800 |

| TVS1014 | 10 | 1400 | 1700 | 4000 | 1200×2200 |

| TVS2016 | 20 | 1600 | 1900 | 4500 | 1600×3200 |

These are major models. Please contact us about drawing force and stroke.

For inquiries about this product

03-6834-2600 sales@toamec.co.jp

Tateishi Koken Products

Special Machine Tool Design and Production

Tateishi Koken deals in various design and production meeting customer’s demands.

Details of business

Special machine tool design and production, machine tool, inspection machine, JIG design and production, welding machine, transportation machine, peripheral devices for robot design and production, peripheral devices for P.F. design and production.

For inquiries about this product

03-6834-2600 sales@toamec.co.jp